Pick a language

Services

DUPLICATION OF PIECES IN METAL

Very often, making a single piece of brass with the rapid prototyping process may not be sufficient.

In many cases it is necessary to have metallic details in quantity. If the white metal is suitable for use then the centrifugal rubber casting is the ideal solution.

If, on the other hand, the component must be made of brass, aluminum or nickel silver, it is necessary to provide for the duplication process with the production of “copy waxes” of the original model.

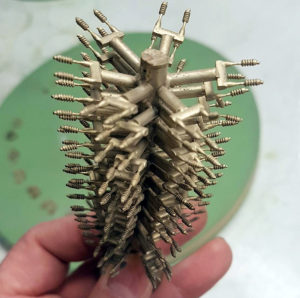

The photo below shows a bunch of fusion with a series of metal shock absorbers produced in series starting from waxes injected into the mold.

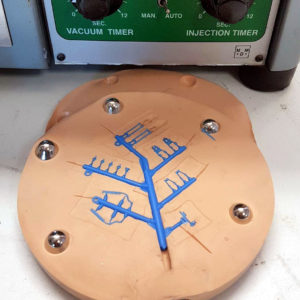

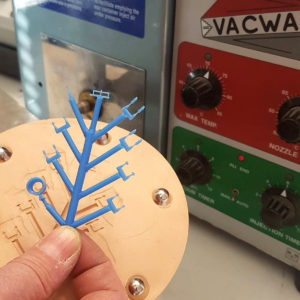

After making the first master in metal and having polished it perfectly, silicone molds are made where a precision wax is injected under vacuum.

These waxes, perfect copies of the original, will then be cast in metal with the lost wax casting process.

The only important warning is to provide in the first master model a dimensional increase on the three “xyz” axes to compensate for the dimensional shrinkage of the whole process.

This method of duplication is particularly indicated for railway modeling where each metal component must be made strictly of brass.

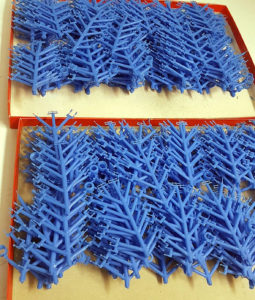

Below are some examples of precision wax castings for railway modeling:

and others injected for automotive model making:

Send us your request by writing to service@tameokits.com, we will reply as soon as possible with further information and quotations.