Pick a language

Services

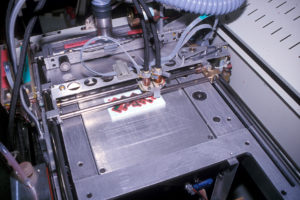

RAPID PROTOTYPING

Rapid prototyping is aimed at the physical realization of the prototype, in a relatively short time, starting from the three-dimensional model of the object (3D CAD).

Prototypes are essential in every step of the product development process, to verify that a model matches the real object or to perform a fitness and functionality test. There are no limits of geometry in the realization of a piece with rapid prototyping.

With our plants we make wax prototypes that are transformed into metal with the lost wax casting process.

With our process we can produce very small pieces (less than 1mm) and large pieces up to the size of the work table (150mm x 150mm x 100mm height).

It is possible to obtain a single piece or to provide for the duplication of metal copies with the duplication process.

We accept CAD files of your production in the following formats:

.IGES .STEP .STL

Our prototyping process is particularly recommended for the production of brass prototypes for the automotive, railway, aeronautic and naval modeling sectors:

It also finds great application also in the industrial design sector.

Below some examples:

Send us your request by writing to service@tameokits.com, we will reply as soon as possible with further information and quotations.

SEGUI IL CANALE WHATSAPP

Tameo Kits Official

per rimanere sempre aggiornato sulle ultime novità

SEGUI IL CANALE